Identification of fluorescent media with UV endoscope

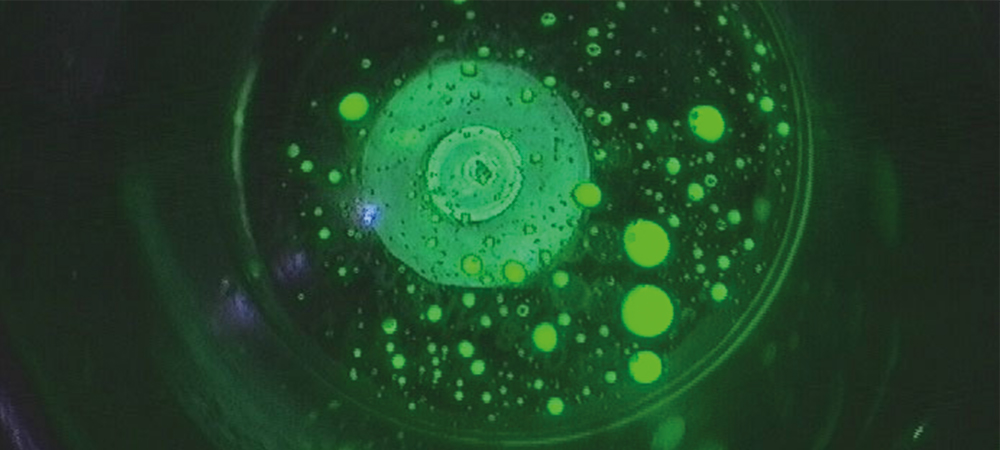

The UVin UV endoscope system of viZaar is equipped with high performance UV-LEDs, which optimally excite fluorescent agents such as many oils, proteins but also common testing agents due to their powerful radiation in the wavelength range of 365nm and thus make them visible.

Such product residues adhering to surfaces and test equipment deposited on material defects can be easily detected and directly documented, even if they are weak.

Wide range of possibilities

The UVin UV inspection system can also be equipped with additional daylight LEDs. Both the UV lighting and the daylight LED can be infinitely adjusted and can also be used simultaneously. Thus, the illumination can be optimally adapted to your needs. With this UV endoscope you can check the purity of systems in food, chemical and pharmaceutical industries and optimise your material testing.

Easy documentation of your inspection on fluorescent media even with small components and narrow cavities thanks to the design as a flexible video endoscope with a probe head of only Ø 13.4 mm.

Surface crack testing with UV videoscopes

For tests on metallic components, two traditional NDT methods for surface crack detection are often used in addition to technically more complex methods. For both of them, you can use our UV endoscope UVin!

Dye penetrant testing with UV endoscopes

Dye penetrant testing, also known as PT testing (Penetrant Testing), makes use of the capillary effect in the case of material separations open to the surface, such as cracks. The penetrant is applied to a material surface and a presumed exposure time is waited for. During this time, the penetrant “creeps” into the material separation and remains there. After cleaning the surface, the test medium remaining in e.g. cracks can be made visible with viZaar’s UV endoscope UVin and thus the material separation can be localized. This dye penetration test does not place great demands on the material to be tested.

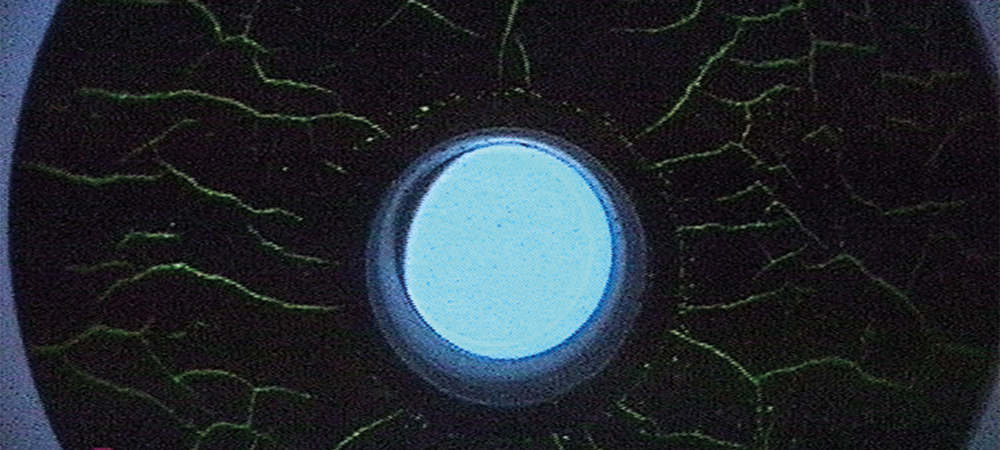

Magnetic particle testing

If the workpiece you want to test is made of a magnetizable (ferromagnetic) material, magnetic particle testing, also known as MT testing (Magnetical Testing) can be performed. Here, magnetic fields are generated or conducted through the component, which are dissipated through material defects or separations near the surface. At the same time, the test surface is wetted with an appropriate test medium containing magnetizable particles. The particles in the test equipment are deposited on the deflected magnetic field lines, which allows defects on the surface of the material to be identified. The great advantage of this method compared to dye penetrant testing is that in magnetic particle testing, material separations near the surface do not have to be open towards the latter. Since the test specimen must be magnetizable, the common stainless steels and non-ferrous metals cannot be tested with this method.

Advantages of UV endoscopes for surface crack testing

Due to their higher sensitivity, both dye penetrant testing and magnetic particle testing are often performed with fluorescent inspection equipment. This makes even small material defects more clearly visible.

Due to the separately adjustable illumination of the UVin UV borescope, the apparent indications often occurring in PT and MT tests (e.g. due to test equipment deposited on turning grooves or dirt) can often be identified as such in the same operation and evaluated separately.

Optimize your purity checks and your materials testing with the UV endoscope UVin.

By the way – our UV endoscope is not the only viZaar inspection camera offering UV illumination. Do you already know the SNK Ultra 365? This is our new tank inspection camera with UV emitter for cleanliness testing and tank inspections.

Contact

Do you have questions regarding our UV endoscope UVin or UV borescopes in general? Contact us! We are experts in the field of industrial videoscopes and endoscopes!

Reach out to us via phone: +49 7432 98375-0 , e-mail: info@vizaar.com or by using our contact form.